Anodising

Working with qualified partners, we offer an anodising service for the aluminium products we process, so that we can offer our customers a turnkey service with a single source.

If you want to give your aluminium profiles greater resistance to corrosion, wear and abrasion, as well as a refined and customisable appearance, anodising is the ideal solution for your needs.

What is Anodising?

Anodising is an electrochemical process that converts the metal surface into a hard, protective oxide layer. This process offers a number of advantages, including:

- Increased corrosion resistance: The oxide layer protects the aluminium from attack by atmospheric agents, chemicals and salinity, making it ideal for applications in aggressive environments.

- Resistance to wear and abrasion: The anodised layer is extremely hard and scratch-resistant, ensuring longer product life.

- Improved thermal insulation: Anodising improves the insulation properties of aluminium, helping to reduce heat loss.

- Customisable aesthetics: The anodised layer can be coloured in a wide range of colours, offering the possibility of customising the appearance of the profiles according to one's taste and needs.

Electrocolouring

We transform your aluminium products by applying vivid, durable colours.

This advanced process uses an electric current to deposit an even layer of colour on the metal surface, ensuring a durable, high-quality finish.

Electrocolouring not only improves the aesthetics of your components, but also increases their resistance to corrosion and wear. With a wide range of colours available and the ability to customise each application, our experienced team ensures excellent results that meet the specific needs of different industries.

Our Services

With RC Ramera, every stage of the project is taken care of in detail with a team dedicated to your every need.

Do you have a special project to develop?

Tell us your idea and find out how we can develop it together.Dedicated technical department

Our team offers support from the first contact, providing a detailed feasibility analysis and advising the customer on the most suitable type of product.

We accompany the customer at every stage of development, from the initial mechanical machining to the subsequent surface treatment stages, right up to the choice of the final packaging type.

Our team of experts is always on hand to ensure that each project is realised with precision and perfectly meets the customer's specific requirements.

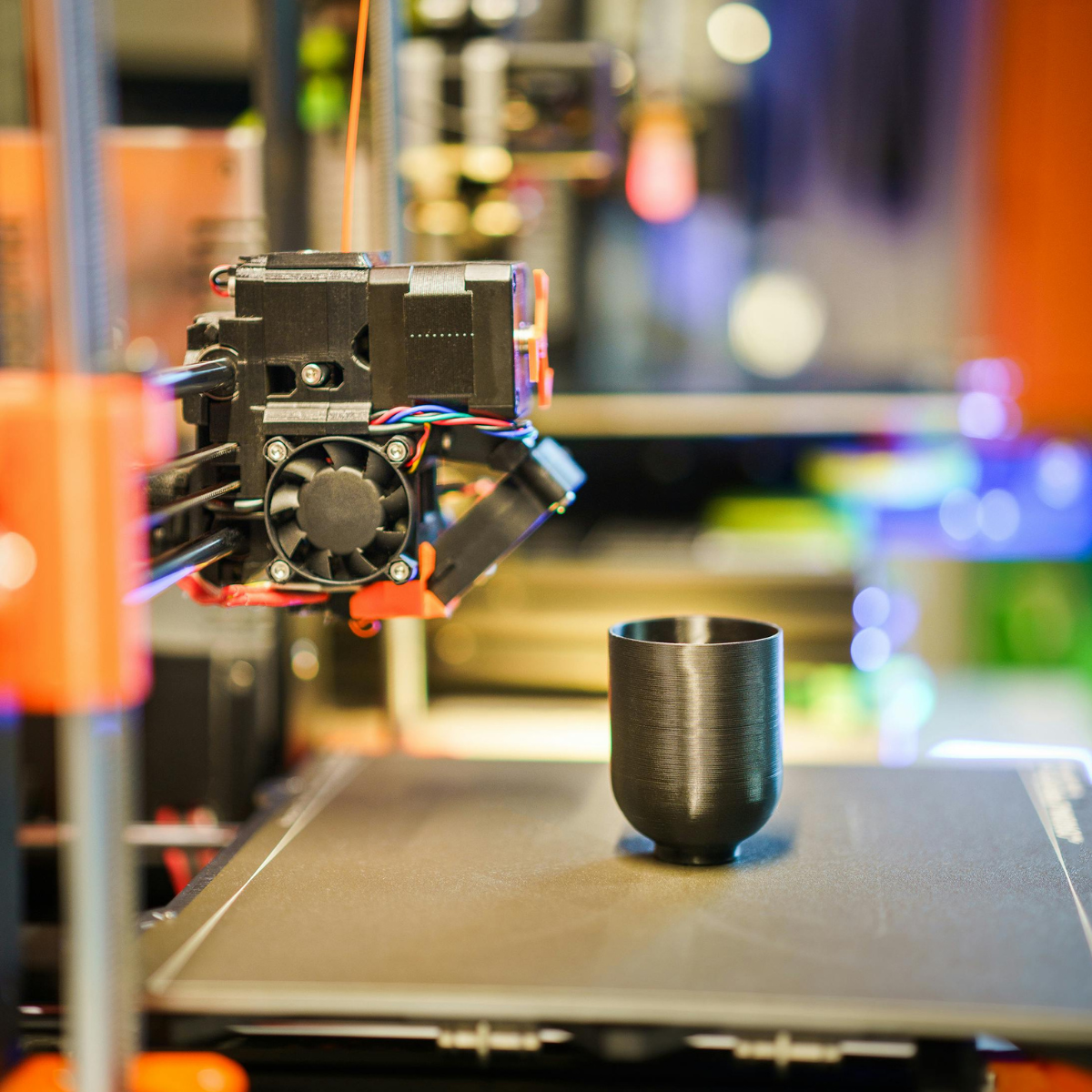

Prototyping

Thanks to our advanced 3D printing technology, we offer the possibility of creating small prototypes of resin products. This service allows customers to concretely visualise the final appearance of the part before metal production.

Prototyping allows you to get a realistic idea of the final product, while also allowing for possible modifications before final production. With our service, we transform ideas into tangible models, facilitating design evaluation and optimisation.