Tumbling

We improve the surface finish of aluminium components through advanced techniques and abrasive materials. We are able to remove burrs, sharp edges and imperfections, resulting in smooth and uniform surfaces.

This process is ideal for preparing parts for subsequent machining steps or for obtaining a high-quality finished product. Tumbling is also particularly useful in sectors such as automotive, aerospace and mechanical engineering, where aesthetic appearance and surface precision are paramount.

Our Services

With RC Ramera, every stage of the project is taken care of in detail with a team dedicated to your every need.

Do you have a special project to develop?

Tell us your idea and find out how we can develop it together.Dedicated technical department

Our team offers support from the first contact, providing a detailed feasibility analysis and advising the customer on the most suitable type of product.

We accompany the customer at every stage of development, from the initial mechanical machining to the subsequent surface treatment stages, right up to the choice of the final packaging type.

Our team of experts is always on hand to ensure that each project is realised with precision and perfectly meets the customer's specific requirements.

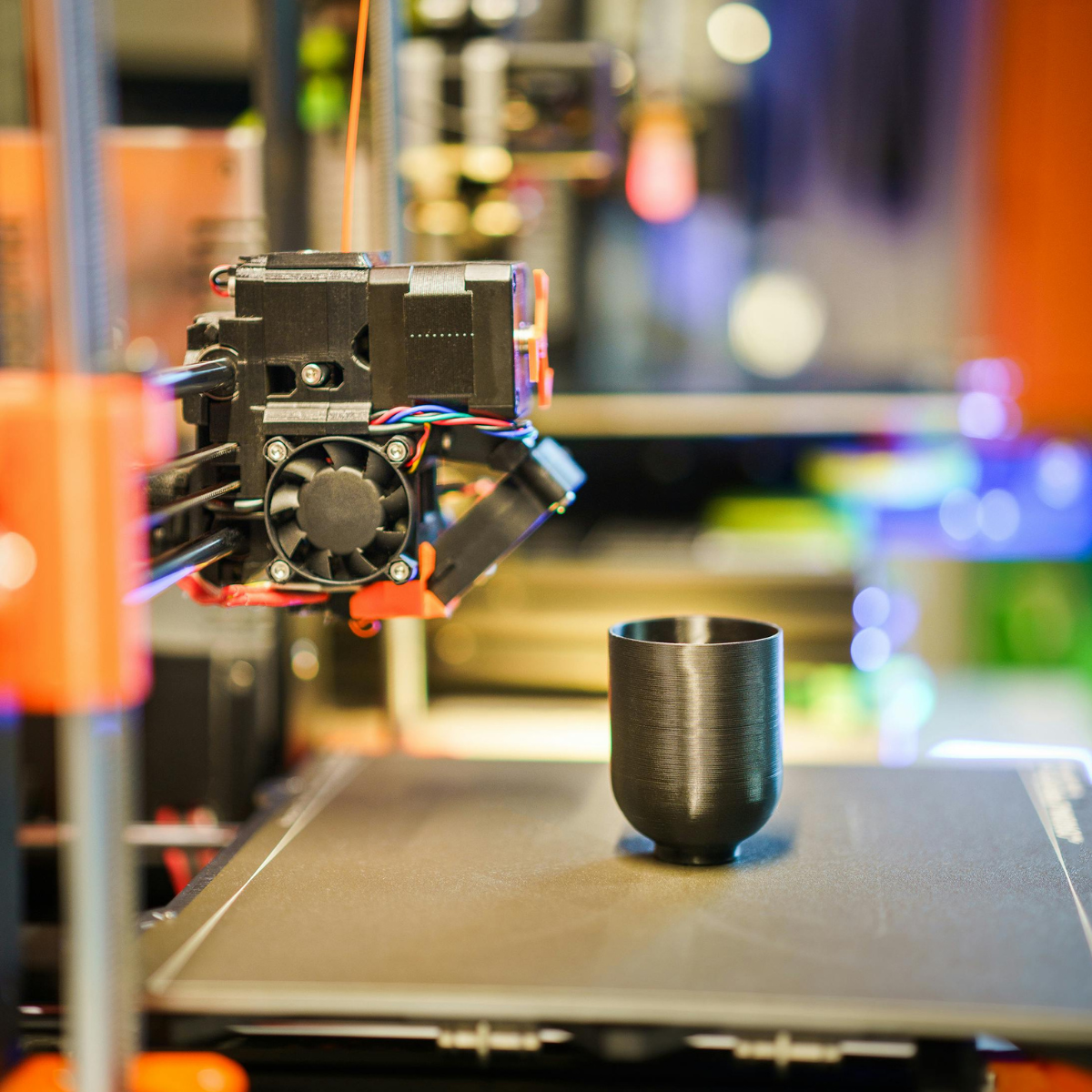

Prototyping

Thanks to our advanced 3D printing technology, we offer the possibility of creating small prototypes of resin products. This service allows customers to concretely visualise the final appearance of the part before metal production.

Prototyping allows you to get a realistic idea of the final product, while also allowing for possible modifications before final production. With our service, we transform ideas into tangible models, facilitating design evaluation and optimisation.